1966 big blockchevelle ignition coil wiring diagram pdf chev

The 1966 Big Block Chevelle ignition system is a critical component, relying on the ignition coil, distributor, and spark plugs. The wiring diagram is essential for understanding circuit connections and color codes, ensuring proper installation and troubleshooting. It guides the flow of power from the ignition switch to the coil, highlighting safety precautions like disconnecting the battery. This system’s efficiency depends on accurate wiring and component functionality, making it vital for optimal engine performance.

1.1 Overview of the 1966 Chevelle Ignition System

The 1966 Chevelle’s ignition system is a crucial part of its engine, responsible for generating the spark needed for combustion. It includes the ignition coil, distributor, spark plugs, and a wiring harness. The wiring diagram is essential for understanding how these components connect and function together. Proper installation ensures the system operates efficiently, while incorrect wiring can lead to issues like misfires or electrical shorts. Safety is paramount, with steps like disconnecting the battery before any work. The ignition system’s design ensures reliable performance, making it vital for the overall functionality and longevity of the vehicle.

1.2 Importance of the Ignition Coil Wiring Diagram

The ignition coil wiring diagram is vital for understanding the electrical connections within the 1966 Chevelle’s ignition system. It provides a clear visual representation of how the ignition coil interacts with other components, such as the distributor, spark plugs, and ignition switch. This diagram is essential for proper installation, troubleshooting, and repairs, as it outlines the correct wire colors and connections. Without it, identifying issues like misfires or electrical shorts becomes challenging. The diagram also ensures safety by guiding technicians to disconnect the battery before working on the system. Accurate wiring is crucial for optimal performance, making the diagram an indispensable resource for maintaining the vehicle’s reliability and power.

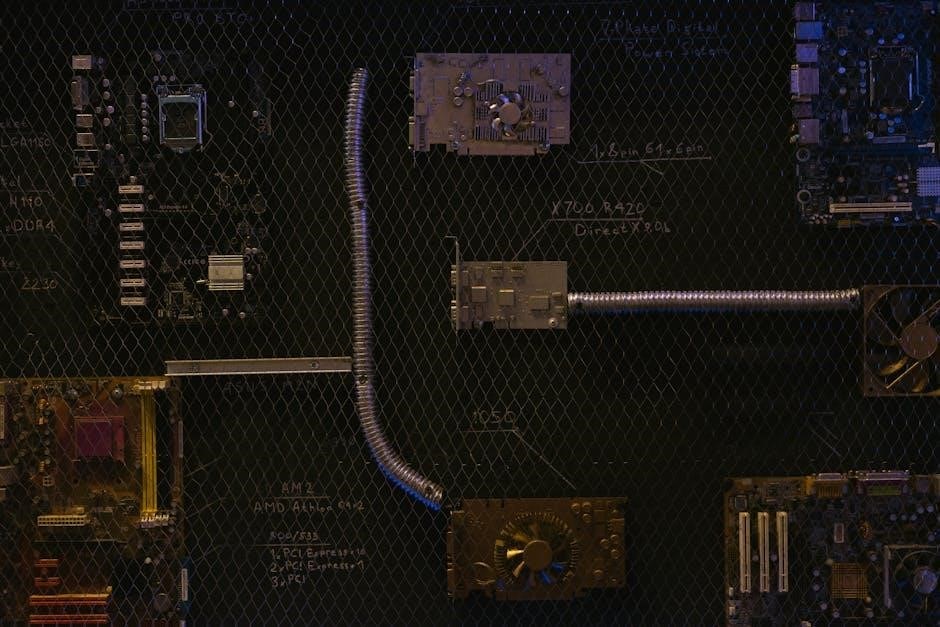

Key Components of the Ignition System

The ignition system comprises the ignition coil, distributor, spark plug wires, and ignition switch. Each component plays a vital role in generating and distributing spark efficiently.

2.1 Ignition Coil

The ignition coil is a vital component, converting battery voltage into high voltage for spark plugs. It consists of primary and secondary circuits, with the primary circuit connected to the ignition switch and battery. The secondary circuit generates the high voltage needed for spark generation. Proper wiring, as shown in the 1966 Big Block Chevelle wiring diagram, ensures efficient energy transfer. The coil’s connection to the distributor and spark plug wires is critical for consistent engine operation. Improper wiring can lead to misfires or no spark conditions, emphasizing the importance of adhering to the diagram’s specifications during installation or troubleshooting.

2.2 Distributor

The distributor is central to the ignition system, responsible for directing high voltage from the ignition coil to the correct spark plug at the precise time. It contains a rotating rotor and cap, which guide the spark to each cylinder in the firing order. The distributor is connected to the ignition coil and spark plug wires, ensuring synchronized spark delivery. Proper alignment and wiring are crucial for optimal engine performance. Issues with the distributor can lead to misfires and poor engine operation, emphasizing the need for accurate connections as detailed in the wiring diagram. Regular maintenance of the rotor and cap ensures reliable spark distribution.

2.3 Spark Plug Wires

Spark plug wires are essential for conducting high voltage from the distributor to the spark plugs. They are designed with resistance to minimize electromagnetic interference. The wires are color-coded for identification, as shown in the wiring diagram, ensuring correct connections. Proper routing away from heat sources and other ignition components is crucial to prevent damage and interference. Over time, spark plug wires can degrade, leading to misfires and reduced engine performance. Regular inspection and replacement are recommended to maintain optimal ignition system function. The wiring diagram provides a clear layout for connecting these wires, ensuring reliable spark delivery to each cylinder.

2.4 Ignition Switch

The ignition switch is a key component in the 1966 Big Block Chevelle ignition system, responsible for controlling power distribution to the ignition coil and other electrical systems. It operates by routing power through a pink wire to the coil when in the “start” or “run” position. The switch ensures the ignition coil receives the necessary voltage for spark generation. Proper wiring, as per the diagram, is crucial to avoid electrical shorts or malfunctions. The ignition switch also incorporates safety features, such as disconnecting power when the engine is off. Regular inspection and cleaning of the switch contacts can prevent issues like intermittent power loss or failure to start the engine. Always disconnect the battery before servicing the ignition switch to avoid electrical shock or damage.

Understanding the Wiring Diagram

The wiring diagram provides a visual guide for connecting components like the ignition coil, distributor, and switches. It uses symbols and color codes to simplify installations and troubleshooting, ensuring proper circuit connections and power flow. Key elements include the ignition switch, fuse block, and spark plug wires, with the pink wire supplying 12V ignition power. Always refer to the diagram for accurate connections to avoid electrical shorts or system malfunctions. Proper understanding ensures safe and efficient system operation.

3.1 Layout and Symbols

The wiring diagram for the 1966 Big Block Chevelle ignition system features a clear layout with standardized symbols. These symbols represent components like the ignition coil, distributor, and spark plug wires. The layout typically organizes components into sections, such as the ignition switch, fuse block, and coil connections. Symbols like circles for connectors, lines for wires, and icons for switches simplify understanding. Color-coded wires are often indicated, with descriptions like pink for 12V ignition power. This visual representation allows users to trace circuits and identify connections easily, ensuring accurate installations and troubleshooting. The diagram’s clarity is essential for safely navigating the electrical system and avoiding potential short circuits or misfires.

3.2 Color Coding of Wires

The 1966 Big Block Chevelle ignition system uses color-coded wires to simplify identification and installation. The pink wire provides 12V ignition power, while the tan wire connects to the fuel pump. Gray wires are typically used for instrument lamps, and dark blue wires are associated with oil pressure. These color codes help technicians trace circuits and avoid misconnections. For example, the pink wire connects to the ignition coil, ensuring proper power delivery. The tan and dark blue wires are essential for auxiliary systems. Understanding these color codes is crucial for accurate wiring and troubleshooting, as incorrect connections can lead to system malfunctions or electrical damage.

3.3 Circuit Connections

The circuit connections in the 1966 Big Block Chevelle ignition system are critical for proper functionality. The ignition coil connects to the distributor via a wire, ensuring spark delivery to the spark plugs. The pink wire provides 12V power from the ignition switch to the coil, while the tan wire connects to the fuel pump. The gray wire is used for instrument lamps, and the dark blue wire connects to the oil pressure sensor. These connections are clearly outlined in the wiring diagram, which helps prevent electrical shorts and ensures proper current flow. Always consult the diagram for accurate connections to avoid system damage or malfunction.

Safety Precautions

Disconnect the battery before starting any wiring work to prevent accidental ignition. Handle electrical components carefully to avoid damage or electrical shocks during installation or repairs.

4.1 Disconnecting the Battery

Disconnecting the battery is crucial for safely working on the 1966 Big Block Chevelle ignition system. Locate the battery, typically in the engine compartment. Always disconnect the negative terminal first to prevent accidental short circuits, then disconnect the positive terminal. This ensures the electrical system is deactivated. Verify by checking if electrical components like the radio or dashboard lights are off. Use appropriate tools for disconnecting terminals, and consider cleaning corroded terminals for better contact. Reconnect the battery in the reverse order after completing the work. This prevents electrical shocks and ensures system reliability.

4.2 Handling Electrical Components

Handling electrical components in the 1966 Big Block Chevelle ignition system requires care to avoid damage or electrical shocks. Always use insulated tools and ensure the battery is disconnected before starting work. Keep spark plug wires and ignition components away from heat sources or moving parts. Avoid touching electrical terminals with bare hands to prevent static discharge. Use proper grounding techniques and ensure all connections are secure. Shielded harnesses are recommended for high-powered engines to prevent interference. Follow the wiring diagram for correct connections and consult repair manuals for specific guidelines. Proper handling ensures system reliability and safety during installation or troubleshooting.

Step-by-Step Installation Guide

Start by disconnecting the battery to prevent electrical shocks. Locate the ignition coil and remove the old one carefully. Install the new coil, ensuring proper connections. Connect the wires according to the wiring diagram, avoiding shorts. Finally, test the ignition system to confirm functionality.

5.1 Preparing the Vehicle

Begin by disconnecting the battery to ensure safety and prevent electrical shocks. Locate a suitable workspace with proper ventilation. Gather all necessary tools, including wrenches and screwdrivers. Consult the wiring diagram to familiarize yourself with the ignition system layout. Secure spark plug wires and other components to prevent interference. Cover nearby surfaces to protect against damage. Double-check the wiring diagram for specific connections related to the ignition coil. Ensure all components are accessible before starting the installation process.

5.2 Disconnecting the Battery

Disconnecting the battery is the first and most crucial step to ensure safety during ignition system work. Locate the battery, typically found in the engine compartment. Identify the negative terminal, usually marked with a “-” sign or colored black. Use a wrench to loosen the nut on the negative terminal clamp. Slide the clamp off the terminal to disconnect it. This prevents accidental power supply and electrical shocks. Wait a few moments to ensure the system is fully de-energized before proceeding. Always consult the wiring diagram to understand the ignition system connections before starting any work.

5.3 Locating the Ignition Coil

Locating the ignition coil is essential for accessing and replacing it. In the 1966 Big Block Chevelle, the ignition coil is typically found under the hood, near the distributor. It is usually mounted on the engine compartment wall or attached to the fender well. The coil is connected to the distributor cap via a spark plug wire and also linked to the ignition switch through a wiring harness. Refer to the wiring diagram to confirm its exact location, as variations may exist. Once located, ensure the area is clear of obstructions for easy access. Always work on a cold engine to avoid any accidental ignition issues.

5.4 Removing the Old Ignition Coil

To remove the old ignition coil, start by disconnecting the battery to ensure safety. Locate the ignition coil, typically mounted near the distributor or on the engine compartment wall. Disconnect the primary wire connected to the coil, usually a thick, insulated wire. Remove any screws or clips holding the coil in place. Gently pull the coil free from its mounting bracket. Be careful not to damage any surrounding wires or components. If the coil is stuck, wiggle it slightly while pulling. Once removed, inspect the area for any remaining wires or brackets that may need to be disconnected or removed. Consult the wiring diagram to confirm all connections are properly identified before proceeding.

5.5 Installing the New Ignition Coil

Mount the new ignition coil in the same location as the old one, ensuring proper alignment and secure fastening. Use the provided screws or brackets to hold it firmly in place. Connect the primary wire to the coil, typically a thick, insulated wire, ensuring it is securely attached. Refer to the wiring diagram for correct connections and color coding. Tighten all connections to prevent loose wires. Reconnect the battery and test the ignition system to confirm proper function. Ensure all electrical components are properly grounded and that no wires are pinched or damaged. This step completes the coil replacement process, ready for system testing.

5.6 Connecting the Wires

Refer to the wiring diagram to ensure accurate connections. Connect the primary wire (typically a thick, insulated wire) from the ignition switch to the positive terminal of the ignition coil. The secondary wire, which carries the spark, should be connected to the distributor cap. Use the correct color-coded wires to avoid confusion. Secure all connections tightly to prevent loose wires, which can cause misfires or electrical issues. Double-check that all wires are properly insulated and routed away from heat sources or moving parts. Once all connections are made, reconnect the battery and test the ignition system to ensure proper functionality.

5.7 Testing the Ignition System

After installing and connecting the ignition components, test the system to ensure proper functionality. Use a spark tester to check for spark at the spark plug wires. Connect the tester to a spark plug wire and crank the engine; a visible spark indicates the ignition coil is working. Check all wires to ensure sparks are present and consistent. Use a multimeter to verify the ignition coil’s resistance matches the manufacturer’s specifications. Start the engine and listen for misfires or unusual noises. If the engine runs smoothly, the ignition system is functioning correctly. If issues arise, refer to the wiring diagram to trace and resolve the problem.

Troubleshooting Common Issues

Common issues include no spark, misfires, or electrical shorts. Use a multimeter to test resistance and voltage. Check spark plug wires and connections for damage or corrosion. Ensure the ignition coil is properly grounded and the wiring diagram matches connections. If no spark, verify the ignition switch and battery connections. For misfires, inspect the distributor cap and rotor. Address shorts by tracing wires and repairing or replacing damaged sections. Always consult the wiring diagram to identify and resolve issues efficiently.

6.1 No Spark at the Spark Plugs

No spark at the spark plugs indicates a disruption in the ignition system. Begin by checking the ignition coil for proper resistance and voltage. Ensure the spark plug wires are securely connected to both the distributor and spark plugs. Inspect the distributor cap for cracks or wear, and verify the rotor is spinning freely. Check the ignition switch and battery connections to ensure power is flowing. Consult the wiring diagram to trace the circuit and identify potential breaks or shorts. If issues persist, test the coil’s primary and secondary resistance. Always disconnect the battery before performing diagnostics to avoid electrical shocks or damage.

6.2 Misfires

Misfires occur when the ignition system fails to generate a spark at one or more cylinders. This can result in poor engine performance, reduced power, and increased emissions. Possible causes include worn or cracked spark plug wires, a faulty distributor cap, or a malfunctioning ignition coil. Consult the wiring diagram to trace the ignition circuit and identify potential issues. Check for loose connections, corrosion, or damage to the spark plug wires and distributor components. Test the ignition coil’s resistance and ensure it matches the manufacturer’s specifications. Addressing misfires promptly is crucial to prevent damage to the catalytic converter and maintain optimal engine operation. Always refer to the wiring diagram for accurate troubleshooting.

6.3 Electrical Shorts

Electrical shorts in the 1966 Big Block Chevelle ignition system can cause sudden, unexpected issues. A short occurs when a live wire contacts a grounded surface, bypassing the intended circuit. This often results in blown fuses or tripped breakers. Check the wiring diagram to identify the ignition coil circuit and spark plug wires. Look for signs of damaged insulation, such as cracks or frays, which can expose wires to metal surfaces. Use a multimeter to test for continuity and isolate the short. Disconnect the battery before repairs to prevent further damage. Ensure all connections are secure and replace any faulty wires to restore proper system function and safety.

Resources and References

Essential resources include repair manuals, online forums, and wiring diagrams. These provide detailed instructions, troubleshooting tips, and visual guides for the 1966 Big Block Chevelle ignition system.

7.1 Repair Manuals

Repair manuals are invaluable resources for understanding and working on the 1966 Big Block Chevelle ignition system. They provide detailed diagrams, step-by-step instructions, and troubleshooting guides specific to the vehicle’s electrical and ignition components. These manuals often include wiring diagrams, which are essential for identifying connections and ensuring proper installation of the ignition coil and related components. GM factory service manuals and aftermarket guides, such as those from Chilton or Haynes, are highly recommended. Additionally, specialized manuals for classic muscle cars offer insights tailored to the Chevelle’s unique ignition system; These resources are indispensable for both novice and experienced mechanics.

7.2 Online Forums

Online forums are a valuable resource for enthusiasts working on the 1966 Big Block Chevelle ignition system. Communities like Chevytalk, ClassicChevy, and Chevelle Tech offer extensive discussions, wiring diagrams, and troubleshooting tips. Members share personal experiences, providing insights into common issues and solutions. These forums are particularly useful for locating rare or specific wiring diagrams, such as the ignition coil wiring diagram for the 1966 Chevelle. Users can also post questions and receive feedback from experienced mechanics and restorers. Additionally, many forums host technical experts who offer free advice, making them an indispensable tool for anyone working on their classic Chevelle’s ignition system.

7.3 Wiring Diagrams

Wiring diagrams are essential for understanding and working on the 1966 Big Block Chevelle ignition system. They provide detailed visual representations of the ignition coil, distributor, and spark plug connections. Available in PDF formats, these diagrams outline the color-coded wires, such as the pink (12V ignition) and dark blue (oil pressure) wires, ensuring accurate installations. They also highlight circuit connections, like the black/white wire for the speedometer and the tan fuel wire. Repair manuals and online forums often host these diagrams, offering step-by-step guides for troubleshooting and modifications. Whether restoring or upgrading, wiring diagrams are indispensable for maintaining the Chevelle’s ignition system, ensuring optimal performance and reliability.

The 1966 Big Block Chevelle ignition system is a vital component for optimal engine performance. Understanding the wiring diagram is crucial for proper installation and troubleshooting. By following the outlined steps and safety precautions, enthusiasts can ensure their Chevelle runs smoothly. Resources like repair manuals and online forums provide valuable support, while wiring diagrams offer clear guidance for circuit connections. Whether restoring or upgrading, adhering to these guidelines ensures reliability and efficiency. The Chevelle’s ignition system, with its coil, distributor, and spark plugs, remains a cornerstone of its power and performance, supported by comprehensive resources and careful attention to detail.